Where Mirror Calm Is Engineered

MirrorRide began as a single-bay workshop obsessed with clarity. Today our studio blends measured light, clean air and quiet tools so paint correction happens with minimal stress and maximum control—perfect for India’s heat, dust and monsoon swings.

- Negative-pressure wash bay for controlled rinse

- Tri-spectrum inspection lights mapped by zones

- Quiet pad library and calibrated torque tools

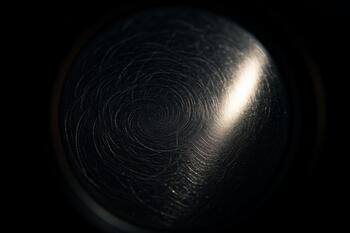

Lighting Lattice

Swirl, haze and ghosting reveal themselves under structured light—not random daylight. Our lattice uses stripe, cross and spot sources, then steps intensity to avoid glare while you still see real defects.

Toolbench Telemetry

Numbers keep us honest: pad rotations logged, microns preserved, noise kept low. Below, counters tick to the averages we maintain across jobs.

0%

Average Cut Reduction

0

Pads in Rotation

0 dB

Noise Below Bay Avg

0 µm

Safe Thickness Margin

Studio Principles & Calibration Notes

We build calm gloss through repeatable steps, not shortcuts. The notes below explain why our bay is arranged the way it is and how we keep outcomes steady across heat, dust and seasonal rain in India.

Every panel enters the same decision tree: measure, mask, cut, refine, preserve. Our technicians learn to pause before each pass and ask whether the next motion actually reduces defect without raising the surface temperature or thinning a vulnerable edge. The method sounds slow; in practice, it prevents backtracking and delivers a finish that calms down under street lighting instead of glowing in patches for a week and then collapsing.

The light lattice is not only bright—it is mapped. We use a tri-spectrum arrangement to expose swirls, haze and holograms at different angles. When a panel leaves one zone and enters the next, the technician knows which type of defect should still be visible. If the wrong artifact is present, we dial back and correct immediately, not at the end of the job.

- Measure first. Paint thickness guides the whole plan; we guard edges and crowns long before polish touches clear coat.

- Isolate variables. One change per step—pad, liquid or machine—so the result has a clear cause.

- Keep tools quiet. Lower vibration means better control, less fatigue and cleaner transitions on curved panels.

- Air discipline. Dust should exit the bay, not orbit the car. Negative pressure and point extraction reduce recapture.

- Finish under neutral light. No perfume lighting; if the finish looks calm under our arch, it will look calm on the ring road.

- Document and learn. We keep short logs: pads used, microns preserved, and what we’d do differently next time.

Our liquids are selected for low dust and predictable wipe-off. Heavy cut is reserved for real leveling, not as a default opening move. Where clear coat is thin, we accept that some defects should remain reduced rather than erased. This restraint is why vehicles we corrected still look composed six months later, even after monsoon runs and weekly commutes.

“Correction is not a fight with paint. It’s a conversation with the clear coat about what it can give without losing its voice.”

- Edge Guard

- Tape, reduced pressure and wider pad overhang to avoid bite lines.

- Heat Window

- Short cycles, slower arm speed, and breaks to keep surface temps stable.

- Refinement Loop

- Two-step clarity pass where soft clears would otherwise haze after cut.

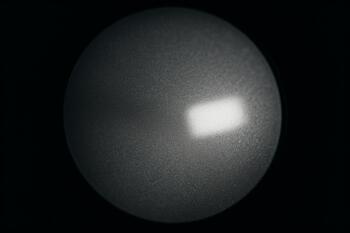

Clean Air Canopy

Correction needs calm air. Our bay circulates through HEPA columns and negative-pressure vents so dust exits before it settles. The particle field below drifts toward the extractor—watch the flow lines pull specks away.

Water Loop Discipline

We minimise waste without compromising safety—softened feed, filtered return, measured pressure. Ripples inside the gauge pad echo how the loop cycles during a careful rinse.

Quiet Bay Acoustics

Sound fatigue reduces focus. Our ceiling baffles and tool mounts keep the bay hushed, so finishing passes stay steady. A pair of wave paths glides across, showing how echoes are damped.

Color Harmony Bench

Spectro scans guide blending so repaired panels melt into factory tone. Our bench keeps hue, saturation and value in a tight window; the swatch simulator below reacts as you move across it.

Bay Flow Map

From wash to refinement to seal—our path is linear, with tools staged to the left of travel so cables never cross paint. The map animates a calm lap.

Delivery Light Walk

Before handover we stroll a short loop under the inspection arch—mirrors, edges, glass, tyres—so you leave knowing exactly what we did and when to return. The checkpoints pulse in sequence.

Aftercare Playbook for Indian Cities

Good habits keep finishes calm between visits. This playbook covers quick, realistic routines for heat, dust and monsoon—no expensive gadgets, just steady care.

Weekly light rinse. A low-pressure pre-rinse releases dust without pushing grit into the clear coat. Follow with a single bucket topped up with fresh water and a pH-neutral shampoo; refresh the surface water as soon as it turns cloudy. Work from roof to sills—never the other way around—and park in shade so water doesn’t flash-dry.

Microfiber discipline. Keep three stacks: glass only, exterior paint, and interior surfaces. Once a towel hits the ground, retire it to interior duty. Avoid fabric softeners; rinse towels warm with a little detergent, then air-dry. A clean towel behaves like a soft brush, not sandpaper.

Monsoon routine. Rinse the lower half after every rain day. Road film hardens quickly and becomes abrasive. Dress rubbers lightly, clear the wiper path with a damp towel and a drop of glass cleaner, and check door drains so they don’t hold water against the seam.

Do

- Use shade whenever possible; cool panels clean better.

- Swap to a fresh mitt when it feels draggy or loaded.

- Blot water with a drying towel; don’t grind.

- Clay only when you feel bonded grit, then refine.

Don’t

- Scrub bird drops dry—soften first with rinsing.

- Use kitchen towels on paint or infotainment screens.

- Chase mirror gloss in direct sun; it lies.

- Ignore tyres and trims; they frame the finish.

How often should I top up a ceramic?

Expect a quarterly topper if the car lives outdoors and runs daily. After a proper decon, a light topper restores beading and slickness; it also keeps wash time short because dirt has less to grab.

What about touchless drive-through washes?

Use only in emergencies. Detergents may be harsh and recycled water can carry grit. If you must, rinse at home the same day and refresh protection.

Can I dry with compressed air?

Yes—keep pressure reasonable and angle the nozzle along the surface, not into gaps. Air is great for mirrors, badges and lug nuts where towels snag.

If in doubt, send us a quick photo and a line about the situation—sap, paint transfer, water spots. We’ll reply with a safe, simple plan that fits the products you already own. The goal is not perfection every weekend; it’s a car that still looks composed on Thursday evening.

Owner Lounge & Brew Bar

While we work, you can watch the bay through acoustic glass and sip a light roast. The steam pad below sends gentle plumes upward—calm like our workflow.

Method Wall & Safety

Every car gets a visible checklist—tools checked, pads labeled, torque set. Items tick on in sequence to mirror our pre-flight ritual.

- Tools & Cables Staged

- Pads Labeled · Cut → Finish

- Panel Thickness Measured

- Mask & Edge Protection

- Final Wipe & Photos

Skill Lab · Apprentice Clinic

We train new hands on practice panels—observe, practice, deliver. Columns fill as you view the board; the goal is consistency, not speed.

Micro-Defect Archive

Under a polarized scope we log the city’s usual suspects—hard-water trails, parking-wipe ticks, towel pigtails. Move the loupe to reveal how a refined surface calms the texture.

Community Drives & Care Talks

We love the road as much as the bay. Weekend loops and short care talks keep owners confident—Nagpur ring-road, Pune ghat morning, Bengaluru night loop. The rail lists our recent city hops.